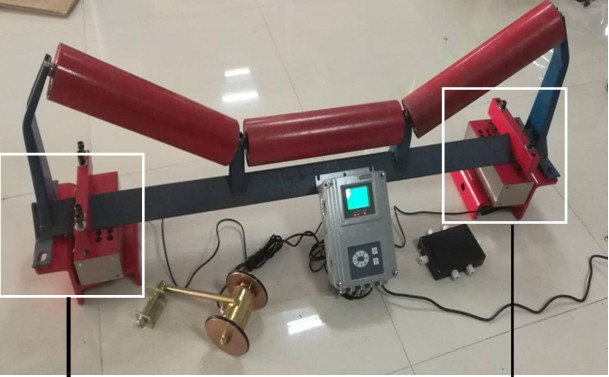

Electronic Belt Weighing Scale for Mining Industry

Features

Description of the Belt Scales

Belt scales are an innovative and reliable weighing solution that is widely used in a variety of industries, including mining, food processing, agriculture, and more. These scales are designed to accurately measure bulk materials as they pass along a conveyor belt, providing precise weight data that is essential for efficient and profitable operations.

One of the key benefits of our belt scales product is that it can be easily integrated into existing conveyor systems, allowing for seamless operation and minimal downtime. We offer a range of belt scale models to meet the unique needs of each industry, from simple and affordable units to advanced and customizable models.

Our belt scales utilize advanced technologies to ensure accurate and reliable weighing, even in harsh operating environments. Our load cells are designed to withstand extreme temperatures, vibrations, and other environmental factors, ensuring consistent and accurate weight readings every time. Additionally, our software is designed to provide real-time data and diagnostic information, allowing for rapid troubleshooting and repair when needed.

With our belt scales, companies can improve their efficiency, reduce material waste, and enhance their profitability. These scales offer significant advantages over traditional weighing methods, such as manual measuring or weighing trucks. Our belt scales are easy to operate and maintain, and they require minimal maintenance and calibration over time, making them an ideal solution for businesses looking to simplify their operations and reduce costs.

Overall, our belt scales product is a reliable and efficient weighing solution that is perfect for a wide range of industries. With advanced technology, ease of operation, and reliable performance, our belt scales are a top choice for companies looking to streamline their operations and achieve optimal efficiency and profitability. Contact us today to learn more about our belt scales and how they can benefit your business.

Specification & parameter

| Model | Accuracy (%) |

Weighing range (t/h) |

Belt speed (m/s) |

Adaptive belt width (mm) |

Belt conveyor inclination | Load cell (PC) |

Weighing roller |

| ICS-XE(14A) | ±0.125 | 5-3000 | 0.2-4 | 500-2400 | ≤6 | 4 | 4 |

| ICS-ST4(17A) | ±0.25 | 5-3000 | 0.2-4 | 500-2400 | ≤18 | 2 | 4 |

| ICS-ST4(17B) | ±0.25 | 5-3000 | 0.2-4 | 500-2000 | ≤18 | 2 | 2 |

| ICS-ST2(20A) | ±0.5 | 1-2000 | 0.2-4 | 500-1400 | ≤18 | 1 | 2 |

| ICS-ST2(20B) | ±0.5 | 1-2000 | 0.2-4 | 500-1400 | ≤18 | 1 | 1 |

| ICS-DT(30A) | ±0.5 | 1-2000 | 0.2-4 | 500-1400 | ≤18 | 2 |

detail

Features

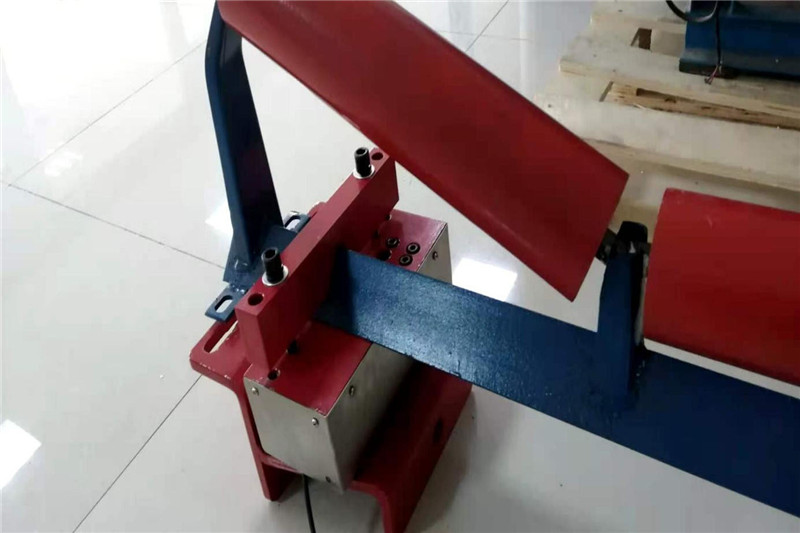

1. Modular design, good versatility. The modular belt scale is a weigh module that pre-assembles a load cell and force transfer mechanism. The field roller is reinstalled into the field weighing roller and connected to the weigh module to form a weigh bridge. Since there are no limitations of traditional weighing trays, the choice of belt scale is almost unlimited by the conveyor bandwidth, as long as the right range of weigh modules is selected.

2. The modular belt scale eliminates the need for traditional bridges, expanding the range of sensor applications.

3. Convenient use for production. Since the four components of the belt scale are equipped with general equipment, the manufacturer can stock up for mass production, which greatly shortens the production cycle

4. Convenient transportation. Since there is no quadrilateral weighbridge, the transport weight and volume are greatly reduced, which facilitates the long-distance transportation of the equipment.

5. Easy to install. There is no heavy bridge, no need to use large lifting equipment for installation, and one or two people can complete the installation on site, which greatly shortens the installation cycle and reduces the installation cost

6.Easy to maintain. Since there is no lever pivot point and no movable parts, there are problems such as fulcrum wear. Leverless scale frame, large scale body, zero point change caused by surface dust.

7. Improve accuracy. Since the weigh module is pre-installed in the factory, the load cell is not directly connected to the structural parts, the sensor force is greatly improved, the structural stress and installation accuracy are affected little, and the belt scale is improved. In addition, since there is no weighing bridge, the tare weight of the sensor becomes smaller, and the effective use of the scope of use of the load cell also improves the accuracy of the belt scale.

detail

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat