Quantitative Packaging Machine

Video

Description of the Quantitative Packaging Machine

Quantitative Packaging Machine, the ultimate solution for all your packaging needs. This state-of-the-art machine is designed to provide precise measurements and optimal performance in packaging operations. With its advanced technology, the Quantitative Packaging Machine is capable of accurately filling and weighing a wide range of products, including grains, powders, and liquids, ensuring consistent quality in every package.

The Quantitative Packaging Machine features a user-friendly interface that allows for easy operation and maintenance. Equipped with a durable stainless steel body, this sturdy machine is built to last and can withstand the demands of even the busiest production lines. Whether you're packaging food items, pharmaceuticals, or any other type of product, the Quantitative Packaging Machine is the perfect choice for your business.

One of the key features of the Quantitative Packaging Machine is its high output capacity. This machine can produce up to 60 packages per minute, making it ideal for large-scale production runs. Its adjustable speed and precision make it easy to achieve the perfect weight and fill volume every time. The machine also comes equipped with an automatic servo filling system that ensures uniformity and accuracy, improving your overall production efficiency.

The Quantitative Packaging Machine is designed to be adaptable and can accommodate a variety of packaging sizes and shapes. Its flexible design allows for quick changeovers between different package types, making it easy to switch between products without any unnecessary downtime. Additionally, the machine features a simple, tool-less adjustment mechanism that makes it easy to fine-tune the settings and achieve optimal results.

With its energy-efficient design, the Quantitative Packaging Machine can help reduce your production costs. The machine consumes less power than traditional packaging machines, resulting in lower electricity bills and a greener operation. Its low maintenance requirements and durable build also help save on maintenance costs, making it a smart investment for any business looking to improve its bottom line.

The Quantitative Packaging Machine is a reliable, versatile, and efficient solution for all your packaging needs. With its advanced technology, high output capacity, and consistent performance, this machine is sure to provide a significant boost to your production efficiency and profitability. So why wait? Contact us today to learn more about this innovative machine and how it can benefit your business.

Machine details

Technical Parameter

|

Items |

Specification |

Goods Pic |

|

Film thickness |

Thickness 0.03-0.1mm |

720G packaging machine Host |

|

Film width |

Max.720mm |

|

|

Bagging length |

50-500mm(L) |

|

|

Bagging width |

50-350mm(W) |

|

|

Air pressure |

0.65mpa |

|

|

Film roll diameter |

Max.350mm |

|

|

Packing speed |

Made to order |

|

|

Power supply |

380V,50/60HZ,2.8Kw |

|

|

Machine dimension |

1500(L)*1350(W)*1980(H)mm |

|

|

Weight |

450Kg |

|

|

Hopper |

5L |

BS-14-5L Combination Scale |

|

Packed weight |

1-5000g |

|

|

Packing precision |

<100g ±2%;100-5000g ±1% |

|

|

Power supply |

380V 50/60HZ |

|

|

Dimension |

1250mm*100mm*1400mm |

|

|

Material |

304 stainless |

304 stainless steel platform |

|

Measurement |

2000*2000*700 |

Technical Parameter

|

Items |

Specification |

Goods Pic |

|

Transport speed |

0-17m/min |

Big tilt angle carrier rising machine |

|

Power |

2.2KW |

|

|

Big hopper |

200L |

|

|

Small hopper |

2L |

|

|

Power supply |

380V 50/60HZ |

|

|

Material |

304 stainless |

|

|

Measurement |

3000(L)*650(W)*3750(H)mm |

|

|

Conveyor material |

304 stainless |

|

|

Voltage |

220V 50HZ |

|

|

Power |

2.2KW |

|

|

Transport speed |

0-17m/min |

|

|

Transport speed |

30m/min |

Finished goods transporting machine |

|

Conveyor material |

Food grade(PP) |

|

|

Voltage |

220V,50HZ |

|

|

Power |

200W |

|

|

Dimension |

1600mm(L)*520mm(W)*1000mm(H) |

|

|

Gentle tips: A packaging machine or a production line is equipped with a bag former. Bags with different product packaging widths need to use an additional bag former. If only the length of the product packaging bag changes, there is no need to purchase a bag former. Set it in the packaging machine That's it. (An additional set of bag formers is 3,800 yuan if necessary) |

Plastic bag shaping machine |

|

Configuration List

|

Seq |

Accessories |

Brand |

Country/Area |

|

1 |

Touch sensitive screen |

Siemens |

Germany |

|

2 |

PLC |

Siemens |

Germany |

|

3 |

Servo motor |

Siemens |

Germany |

|

4 |

Horizontal cylinder |

AirTAC |

TAIWAN |

|

5 |

Vertical cylinder |

AirTAC |

TAIWAN |

|

6 |

Cutting cylinder |

AirTAC |

TAIWAN |

|

7 |

Two units system |

AirTAC |

TAIWAN |

|

8 |

Film delivering cylinder |

AirTAC |

TAIWAN |

|

9 |

Solid state relay |

GOTEK |

TAIWAN |

|

10 |

Intermediate state relay |

IDEC |

JAPAN |

|

11 |

Photoelectric eye |

Autonics |

SOUTH KOREA |

|

12 |

Power |

Siemens |

Germany |

|

13 |

winding motor |

TY TRANS |

TAIWAN |

|

14 |

Temperature control meter |

AISET |

SHANGHAI |

|

15 |

Access switch |

GOTEK |

TAIWAN |

|

16 |

Coding machine |

DINGSHENG |

WENZHOU |

|

17 |

Electromagnetic valve |

AirTAC |

TAIWAN |

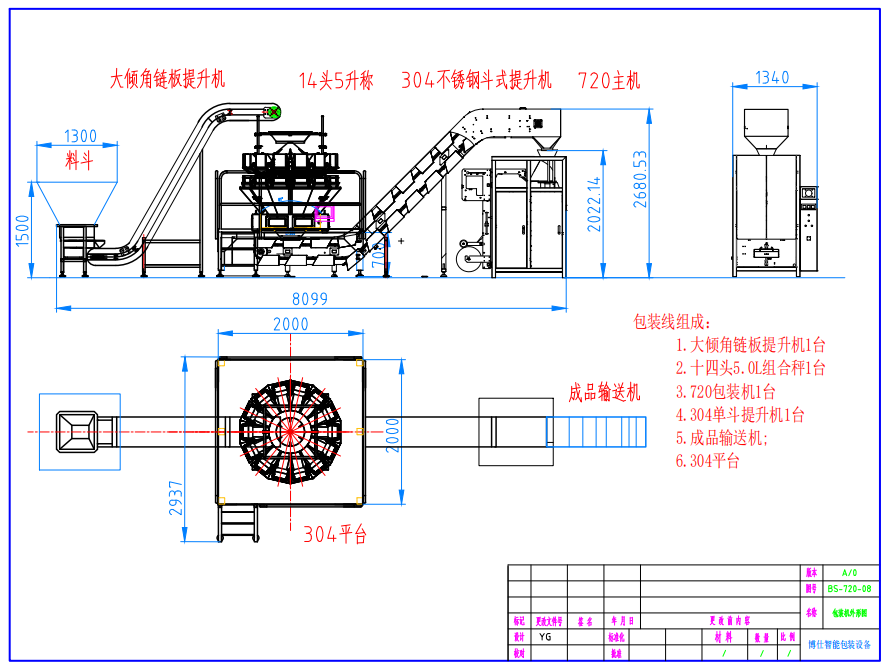

System Details

①14-head 5.0L combination scale 1 unit

②720 packaging machine 1 unit

③ big volume rising machine 2 units

④ finished goods transporting machine

II. Primary Functions

*Fully automatic material lifting;

*The entire process of metering, filling bag making, and finished goods output.

*High measurement accuracy, high efficiency, free of broken material.

III.Application Industries

It is widely applied for industries where needs quantitative weighing and packaging of various materials such as granules and blocks.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat